Fiber Optic Cable vs Copper Cable: Which One Will Power the Future of Your Network?

Choosing the right foundation for your network infrastructure is a pivotal decision. At the heart of this choice lie two primary contenders: fiber...

12 min read

Tony Ridzyowski

:

Updated on July 28, 2025

Tony Ridzyowski

:

Updated on July 28, 2025

A single mismatched power cord can destabilize your entire data center. Small as it may seem, the wrong cable—too long, the wrong gauge, or incompatible with your equipment—can trigger overheating, trip breakers, or cause unplanned shutdowns.

Recent data shows smaller businesses lose an average of $427 for every minute of downtime. Some incidents escalate into six or seven-figure annual losses when factoring in revenue disruption, compliance penalties, customer churn, and reputation damage. And in many cases, it starts with a cable that was never meant for that server, rack, or PDU.

This guide lays out practical, clear steps for choosing the right data center power cords—from voltage matching and connector types to cable management and future-ready planning.

Power cords rarely get the attention they deserve until something goes wrong. Facility managers and IT teams responsible for uptime can’t afford to treat power cables as an afterthought. Every cord in your server rack plays a part in keeping systems online and protected. Choosing well, at the cord level, is the foundation for maintaining reliable, high-performance infrastructure.

Consistent and reliable power is the lifeblood of any data center. High-quality, correctly specified power cords ensure that servers, storage arrays, and networking gear receive stable electrical current, which is fundamental for their continuous operation. Using substandard or incorrect power cords can lead to intermittent connections, overheating, or even complete power loss to a device.

Such disruptions, however brief, can cause system crashes, data corruption, and unplanned downtime. The financial implications of these outages, including lost productivity, recovery expenses, and potential damage to an organization's reputation, far outweigh the initial investment in reliable power solutions and the selection of power cords designed for your specific data center equipment.

Safety within a data center environment is a non-negotiable priority. Power cords, if not chosen or handled correctly, can present significant electrical and fire hazards. Compliant power cables, manufactured to meet stringent safety and quality standards, are designed to handle their rated electrical loads without risk of overheating or insulation breakdown. This includes using cords with appropriate wire gauge, durable jacketing, and securely molded connectors.

Furthermore, safe handling practices, such as avoiding overloading circuits, regularly inspecting cords for damage, and ensuring proper connections, are essential to mitigate risks like electrical shock, short circuits, and fires, thus protecting both personnel and expensive data center assets.

Data centers operate within a framework of local, national, and international regulations and industry standards. These standards, such as those set by Underwriters Laboratories (UL) in North America or the International Electrotechnical Commission (IEC) globally, dictate specific requirements for electrical components, including power cords.

Using power cords that are certified to these standards is crucial for ensuring regulatory compliance. This not only helps in passing safety inspections and audits but also signifies a commitment to operational excellence and risk management. Non-compliant cords can lead to penalties, void equipment warranties, or even legal liabilities in the event of an incident, making the selection of certified power solutions a critical aspect of data center management.

Various cords and connectors are designed to meet the power requirements of specific equipment, address regional standards, and handle different levels of electrical load. Understanding these common cable types helps ensure compatibility and reliability across your entire infrastructure.

These standardized connectors are widely used in data centers around the world, offering reliable and safe connections for IT equipment.

C13 Connector: Rated for up to 10A at 250V, the C13 is commonly used to power desktops, smaller servers, switches, and network equipment. Its compact size makes it ideal for tightly packed server racks and helps reduce clutter.

C19 Connector: With a higher current rating of 16A at 250V, the C19 connector is designed for high-power devices such as large rack-mount servers, enterprise storage units, and uninterruptible power supplies (UPS). Its larger form factor ensures safe handling of increased electrical loads.

C14 Connector: This is the male inlet that pairs with the C13 plug, often found on the back of equipment such as servers and PDUs. Power cords with a C14 plug on one end and a C13 connector on the other are among the most common for connecting devices to a PDU or power source.

C20 Connector: The C20 is a male inlet that pairs with the C19 connector, commonly found on high-power equipment or PDUs. C20 to C19 power cords are used for devices requiring more current, such as blade servers or large UPS units.

C15 Connector: This connector is similar in appearance to the C13 but designed for higher temperature applications, such as certain switches or servers with heating elements. Always verify wattage and temperature requirements when specifying a C15 cable.

NEMA (National Electrical Manufacturers Association) standards are predominant in North America. These AC power plugs and outlets come in a variety of configurations to accommodate different voltages and amperages, ranging from standard 120V household outlets to specialized 208V or 240V plugs for heavier equipment. Properly matching NEMA plugs to your devices and PDUs is vital for both safety and code compliance in North American data centers.

Certain servers and rack systems demand power cords with higher capacity and greater durability. Heavy-duty cables are constructed with thicker gauge wires and robust insulation materials, such as PVC or thermoplastic elastomer, to withstand higher temperatures, continuous bending, and heavy electrical loads. These cables are essential for powering high-density server racks and mission-critical systems that cannot afford any interruption.

Power Distribution Unit (PDU) cords are purpose-built for linking PDUs to the main power supply or for distributing power from the PDU to individual servers and devices. The most common configurations include C14 to C13 for standard devices and C20 to C19 for higher-powered equipment. Reliable PDU cords are crucial for maintaining balanced and efficient power distribution throughout the data center.

A universal power cord typically refers to a power cord with a standard IEC connector (such as C13) and a region-appropriate plug (such as NEMA 5-15P for North America), allowing it to fit many devices like computers, monitors, and some servers. Keeping several spare cords on hand can help quickly restore power in case a specific cord fails.

A power cord that fits the port isn’t necessarily the right one for the job. Voltage, amperage, connector type, and cord gauge all need to align with the demands of your servers, PDUs, and network gear. That alignment is what ensures stable power delivery and safe operation. Treat every cord as a critical component in your power chain. Getting the right spec from end to end keeps your infrastructure running smoothly and your equipment protected.

Before selecting any power cord, you must thoroughly understand the power requirements of each piece of data center equipment it will connect to. This starts with identifying the correct voltage (e.g., 120V, 208V, 230V) and amperage ratings for your devices. You also need to determine the specific connector type required at both the equipment end and the power source (PDU or wall outlet) end.

Common connector types used in data centers include IEC C13/C14 (typically for lower-power devices like servers and switches) and IEC C19/C20 (for higher-power devices like larger servers, UPS units, and PDUs). North American equipment might also use NEMA connectors (e.g., NEMA 5-15P). For high-density or blade server environments, heavy-duty power cords with higher amperage ratings and robust construction are often necessary to handle the increased power draw safely.

The physical characteristics of a power cord, specifically its length and wire gauge (American Wire Gauge - AWG), are critical for optimal power delivery. A cord that is too long can result in a voltage drop, where the voltage at the equipment end is lower than at the source, potentially leading to improper device function or shutdown.

Conversely, a cord that is too short may not reach, leading to unsafe practices like stretching or using inappropriate extension cords. The wire gauge indicates the conductor's thickness; a lower AWG number means a thicker wire and a higher current-carrying capacity.

Using an undersized gauge (too high an AWG number for the load) can cause the cord to overheat, creating a fire risk and inefficient power transfer. Always choose a cord length that allows for neat routing without excessive slack and an AWG appropriate for the amperage of the connected device and the length of the cord.

The material used for the conductors within a power cord significantly impacts its performance and reliability. Oxygen-Free Copper (OFC) is widely recognized as the preferred conductor material for high-quality data center power cords. OFC has higher conductivity compared to other copper alloys or copper-clad aluminum, meaning it transmits power more efficiently with less resistance.

Lower resistance translates to less heat generation within the cord and reduced voltage drop over its length, contributing to better power quality for sensitive IT equipment. This improved efficiency and lower heat buildup also enhance the safety and longevity of the power cord, making OFC a key factor when selecting power cords for critical data center applications.

The outer jacket of a power cord serves to protect the internal conductors from physical damage, moisture, and other environmental factors. The choice of jacket material should balance durability, flexibility, and suitability for the specific data center environment. A common jacket type is SJT (Service Junior Thermoplastic), which offers good flexibility, durability, and resistance to oil and abrasion, making it suitable for general use in conditioned data center spaces.

Other jacket materials might be specified for harsher environments or where higher temperature ratings are needed. Consider factors like ambient temperature, potential exposure to chemicals, and the amount of handling or movement the cord will undergo when selecting the appropriate jacket type to ensure long-term reliability and safety of your power connections.

Reliable power doesn’t stop at the cord. It depends on how well your entire power distribution setup is planned and managed, from the wall outlet to the server rack. That includes how circuits are loaded, how PDUs are configured, and how cords are routed. Solid power management helps prevent downtime, supports future growth, and keeps everything running.

A critical best practice in data center power management is the de-rating of power circuits and components. Continuous power loads, defined by the National Electrical Code (NEC) as loads that operate for three hours or more, require circuits to be loaded to no more than 80% of their maximum rated capacity.

For instance, a 20-amp circuit should ideally not carry more than a 16-amp continuous load. This 20% de-rating factor provides a safety margin, preventing circuit breakers from tripping due to sustained high loads and reducing the risk of overheating in wiring and power cords. Applying this de-rating principle to your PDUs and the power cords connected to them ensures NEC compliance and enhances the overall safety and reliability of your power distribution system.

For organizations with a global footprint or those that may deploy equipment internationally, understanding and accommodating different international power configurations is essential. Voltage standards, frequencies, and power connector types vary significantly from region to region (e.g., 230V/50Hz with different plug types in Europe versus 120V/60Hz with NEMA plugs in North America).

When selecting power cables, ensure they are compatible with the specific electrical systems of the target country or region. This includes using power cords with the correct plug type for the local outlets or PDUs and ensuring the cords are certified to relevant international standards like IEC, CE, or other specific standards for that region.

Power Distribution Units (PDUs) are fundamental components in data center racks, distributing power from a single input source to multiple pieces of equipment. Basic PDUs offer a simple way to increase the number of available outlets, while intelligent (or smart) PDUs provide advanced features like remote outlet monitoring, individual outlet switching, power consumption metering, and environmental sensor support.

When connecting devices, best practices include evenly distributing the load across PDU circuits, using appropriate length power cords to avoid clutter, and clearly labeling connections. For critical systems, implementing redundancy with dual PDUs is highly recommended. Each server or device with dual power supplies is connected to two independent PDUs, which are in turn fed by separate power circuits. This ensures that if one PDU or power feed fails, the equipment continues to operate without interruption, significantly enhancing uptime.

Getting the right cords in place is only part of the job. How those cables are handled, routed, and maintained plays a big role in keeping your data center stable and secure. Tangled cords can block airflow, hide damage, and lead to unplugged equipment. Consistent cable management and regular safety checks help reduce risk, support cooling, and make maintenance faster and more predictable. It’s a simple way to protect uptime and extend the life of your equipment.

Proper cable management for power cords is essential for several reasons. Clearly labeling both ends of every power cord makes tracing cables for troubleshooting or changes much simpler and faster, reducing downtime during maintenance. Using angled connectors can help in tight spaces within racks, allowing server doors to close properly and reducing stress on the cord and connector. Methodical routing of power cords using cable trays, racks, and ties keeps them organized, prevents tangling, and ensures they do not obstruct walkways or equipment access. Most importantly, well-managed cords improve airflow within server racks, which is critical for efficient cooling and preventing equipment from overheating. This organization also mitigates risks such as accidental disconnections, tripping hazards, and damage to the cords themselves.

Ongoing electrical safety in a data center hinges on the consistent use of high-quality components and adherence to safe practices. Always use power cords that are specifically designed for data center use and carry appropriate safety certifications (e.g., UL). These cords are built to higher durability and performance standards than typical household power cords. Locking power cords, which feature a mechanism to secure the plug to the PDU or equipment inlet, are an excellent investment to prevent accidental disconnections due to vibration or human error, a common cause of server outages. It's vital to understand that data center power cords are engineered to handle higher current loads continuously and often have different connector types (like IEC C13, C19) and jacketing materials compared to standard residential cords. Using the wrong type of cord, such as a light-duty household extension cord for a server, can lead to overheating and fire.

While power strips (often referred to as relocatable power taps or RPTs) and extension cords can offer temporary convenience, their use in a data center environment must be strictly controlled and minimized. If used, they must be heavy-duty, UL-listed, and appropriately rated for the connected load. Avoid daisy-chaining power strips (plugging one power strip into another), as this can easily overload the original circuit and create a significant fire hazard. Extension cords should only be used as a temporary solution and never as a permanent part of the power infrastructure. The ideal approach is to plan power distribution with sufficient PDU outlets and use appropriately sized power cords to directly connect equipment, thereby eliminating the need for most power strips and extension cords and enhancing the overall safety and reliability of the data center’s power system.

Data centers don’t stay the same for long. As workloads grow and equipment changes, so does the demand on your power system. Without a plan, it’s easy to run out of capacity or find out too late that your setup can’t scale. Staying ahead means tracking power usage, designing with flexibility in mind, and building in room for expansion. A well-planned infrastructure handles growth without compromising uptime or safety.

As your organization deploys more servers, storage, and networking equipment, the demand for power will inevitably increase. Strategic scaling of your power supply means planning for this growth in advance. This might involve ensuring that your current data center facility has sufficient incoming utility power capacity or that space and infrastructure are provisioned for additional UPS systems, generators, and PDUs. When adding new server racks, assess their projected power density and ensure that cooling and power distribution can support the increased load. Choosing modular PDUs and UPS systems can also facilitate easier and more cost-effective scaling, allowing you to add capacity incrementally as needed, rather than overprovisioning significantly from the outset.

Regular energy audits are a cornerstone of effective data center power management and future planning. These audits involve monitoring and analyzing power consumption at various levels – from individual devices and racks to entire data center halls. The data gathered from these audits provides valuable insights into current usage patterns, identifies areas of inefficiency, and helps in accurately forecasting future power requirements. Understanding your power draw and PUE (Power Usage Effectiveness) trends allows for more informed decisions about infrastructure upgrades, capacity planning, and the potential adoption of more energy-efficient technologies. This proactive approach helps avoid situations where power capacity becomes a bottleneck to growth or where unexpected energy costs impact budgets.

Resilience is key to maintaining high availability in a data center. Building a resilient power infrastructure involves implementing solutions that can withstand component failures or utility outages. Modular power solutions, such as modular UPS systems and busway power distribution, offer flexibility and scalability, allowing for easier maintenance and upgrades without significant downtime. Redundant systems are critical: Uninterruptible Power Supplies (UPS) provide immediate backup power during short outages and condition incoming utility power, while backup generators can sustain operations during extended utility failures. Implementing N+1 or 2N redundancy for these critical power components ensures that there is always a backup available, safeguarding the continuous operation of your data center devices.

The technology landscape is constantly evolving, with new generations of servers often having different power and cooling characteristics. Data center managers must continuously monitor power demand and be prepared to adapt their power distribution infrastructure. This includes tracking power density trends at the rack level and understanding how new deployments will impact overall consumption. Embracing energy-efficient designs for power distribution, such as using high-efficiency UPS systems, optimizing voltage levels (e.g., 400V distribution), and selecting efficient power cords and PDUs, can help manage growing demand while controlling operational costs. A flexible and adaptable power infrastructure is crucial for supporting the dynamic needs of modern data centers and ensuring long-term sustainability.

Every decision about power cords has a direct effect on system uptime, electrical safety, and compliance, especially in environments that can't afford disruptions, like schools, government facilities, and enterprise data centers. Getting the right data center power cords in place means more than checking specs. It means aligning voltage, connector types, cord length, and cable management with the demands of your equipment and your future growth plans.

TTI Cable helps organizations make those decisions with clarity and precision. Our team brings deep technical expertise and a full catalog of data center-grade power cables, connectors, and PDUs designed for consistent, efficient power delivery. We simplify the process so you can focus on your core operations while knowing your infrastructure is built for resilience and performance.

Power reliability starts with the right components. Don’t risk downtime over a poorly matched cable. Explore premium power cords at TTI Cable or contact Turn-key Technologies Inc. for support with power planning, product selection, and infrastructure upgrades.

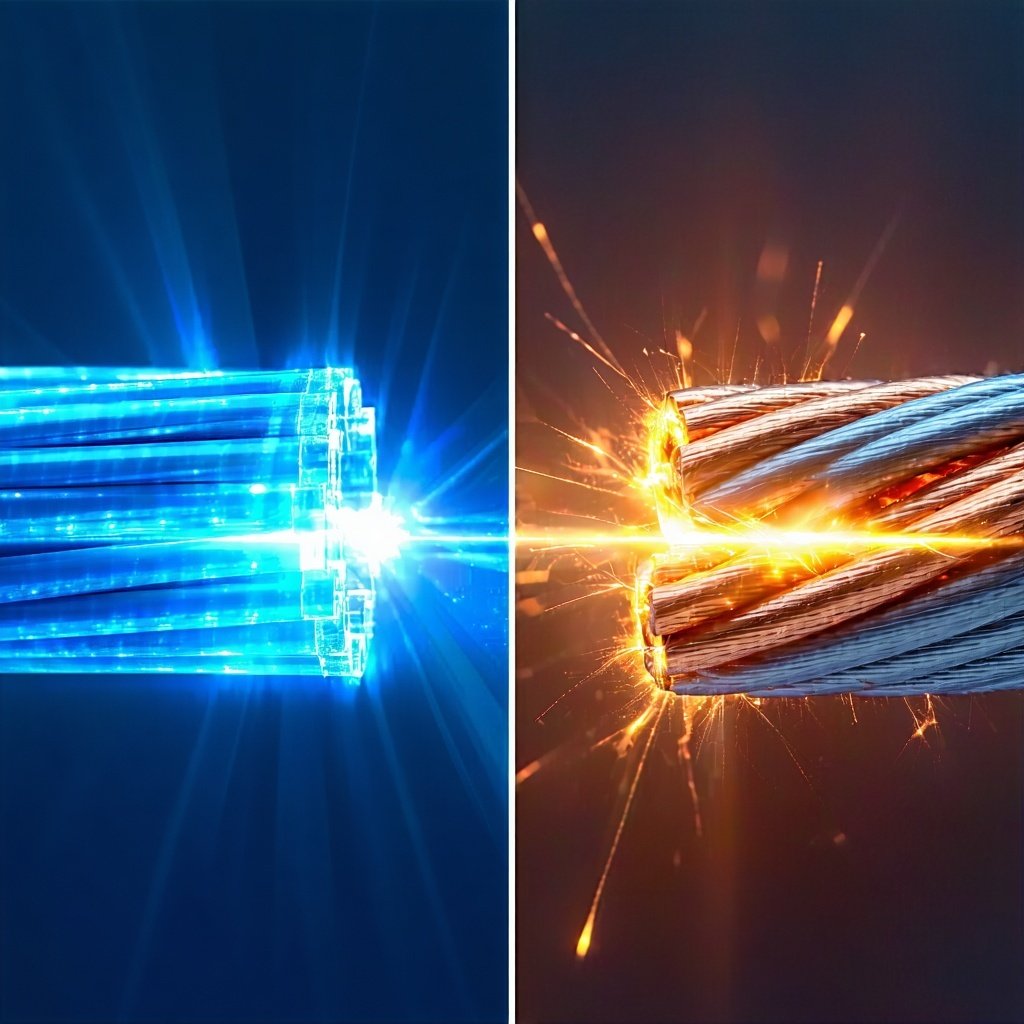

Choosing the right foundation for your network infrastructure is a pivotal decision. At the heart of this choice lie two primary contenders: fiber...

Organizations today rely on high-speed data transmission to keep up with increasing workloads, large data transfers, and real-time applications. From...

1 min read

How do you extend your network without tearing it apart? Let’s say your team is upgrading a campus network, and the new building across the street...